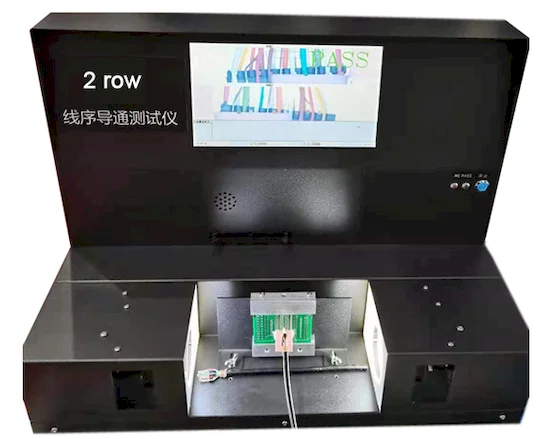

Maximize Efficiency and Accuracy in Wire Harness Testing with the Advanced Double Row Housing Wires Sequence Test Machine

Introduction:

In

today's demanding manufacturing environment, ensuring the quality and

reliability of wire harnesses is paramount. Introducing the Double Row Housing Wires Sequence Test Machine,

a cutting-edge solution designed to streamline your wire harness

testing processes and guarantee impeccable product performance. This

versatile and intelligent instrument is engineered for comprehensive

testing, going beyond simple wire sequence verification to encompass

continuity, insulation (optional), and even dot matrix printing

capabilities (optional), all within a single, user-friendly platform.

Whether you're producing complex automotive harnesses, delicate consumer

electronics cables, or specialized medical device wiring, this machine

delivers the precision, speed, and adaptability you need to maintain the

highest standards.

Key Features and Benefits:

This

Double Row Housing Wires Sequence Test Machine stands out due to its

exceptional flexibility, intelligence, and wide range of applications.

Let's delve into the core features that make this instrument an

indispensable asset for your production line:

1. Unparalleled Versatility and Adaptability:

-

Modular Testing Modes for Diverse Needs: This machine is not just a single-function tester. It offers a truly

flexible "three-in-one" testing capability. You can configure it for:

-

Wire Sequence + Continuity (Insulation Optional) + Dot Matrix Printing (Optional): This comprehensive mode provides a complete quality check, ensuring

correct wire order, electrical connectivity, insulation integrity (if

equipped), and adding traceability with optional dot matrix printing.

-

Wire Sequence Color + Continuity (Two-in-One): For applications where color coding is critical, this mode verifies

both the correct wire sequence based on color and ensures continuous

electrical paths.

-

Dedicated Wire Sequence Color Testing: If your primary focus is simply verifying the correct color sequence

of wires, this mode provides a streamlined and efficient solution.

-

Wire Sequence Color + Point Search (Two-in-One): This unique combination not only tests the wire sequence and color but

also incorporates a point search function, beneficial for identifying

specific points within complex harnesses.

-

Specialized "Wire Sequence + Terminal Not in Place + Continuity" (Three-in-One) (Optional): For specialized applications, particularly with electronic components

or assemblies, this optional mode adds an extra layer of quality control

by detecting if terminals are not properly seated or connected,

alongside wire sequence and continuity checks. This is invaluable for

composite products where connection integrity is crucial.

-

Customizable Test Sequences: Tailor the testing process to your specific product requirements. The

machine allows you to define "single selection" or "multiple selection

custom test sequences" for both wire sequence and conduction testing.

This adaptability ensures the machine seamlessly integrates into your

existing workflows and handles diverse product variations.

-

Designed for Modern Connectors: The 8-AB double-row design is specifically engineered to handle the intricate wiring configurations of modern connectors like HDM1, TYPE-C, USB,

and other core wire sorting applications. This makes it ideal for

manufacturers working with current and future generation electronic

devices.

2. Intelligent Operation for Enhanced Efficiency and User Experience:

-

Intuitive Human-Machine Interface (HMI): Say goodbye to complex setups and steep learning curves. The machine

boasts an intuitive HMI that is exceptionally easy to set up, learn, and

operate. Its user-friendly design minimizes training time and

maximizes operator efficiency. Furthermore, remote guidance

capabilities are available, allowing for efficient troubleshooting and

support, even for customers in remote locations.

-

Automatic Identification and Error Prevention: Intelligent algorithms automatically identify the same color wires and

front/back sides during debugging. This smart feature eliminates

manual guesswork and significantly simplifies the setup process. During

testing, the housing can be placed in any orientation – front or back –

further streamlining the workflow and minimizing potential errors.

-

Editable Files and Automated Pass/Fail Judgment: Save valuable time and ensure consistency with editable test files and

parameters. You can create and store test programs for different

products and recall them instantly for future use. The machine

automatically executes the test, determines if the harness PASSES or FAILS (NG),

and prominently displays the result. Crucially, upon detecting a

failure (NG), the machine automatically locks, preventing further

processing of faulty harnesses and ensuring only compliant products move

forward.

-

Advanced Filtering and Specialized Product Detection: The machine incorporates intelligent filtering capabilities to

effectively ignore printing or markings on the wire body, ensuring

accurate color detection. For special products requiring precise

assembly, the machine can reliably detect whether components, such as

terminals, are correctly and fully inserted ("in-place insertion

detection").

-

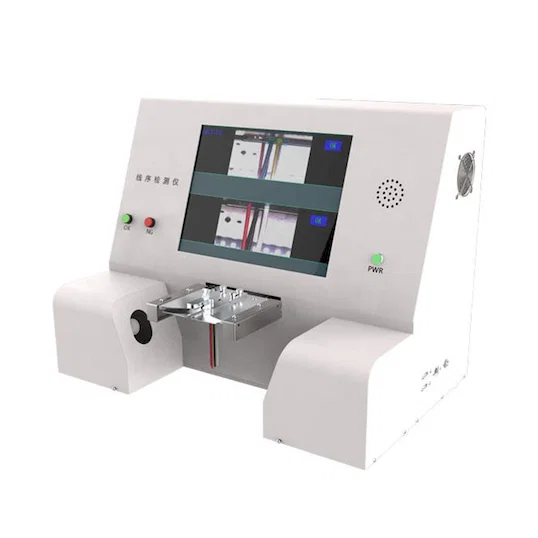

Comprehensive Result Display and Data Management: Test results are clearly presented through multiple channels: a

bright, easily readable screen display, visual indicator lights for

quick status checks, and voice prompts for auditory feedback. Beyond

immediate results, the machine allows for the storage and export of

comprehensive test data. This feature is invaluable for quality control,

traceability, and in-depth analysis of production trends.

-

Advanced Conduction Testing: The machine's robust conduction testing capabilities are capable of detecting up to 64-point open circuits, dislocations, instantaneous disconnections, and point detection.

This level of detail ensures even the most subtle wiring faults are

identified, guaranteeing the integrity of the wire harness.

-

Automated Quantity Control: Streamline your production counting and packaging processes. You can

set a target quantity for each good product, and the machine will

automatically trigger an alarm once that number is reached. This feature

eliminates the need for manual weighing or counting, saving time and

minimizing errors.

3. Diversification of Test Products and Broad Application Range:

This

machine is designed to handle a diverse range of wire harness types and

configurations, making it a truly versatile investment:

-

Handles Various Harness Configurations: From single-ended and double-ended to double-row hole and multi-ended, multi-segment non-sequential wiring harness products, this machine can handle a wide array of complexities.

-

Accommodates Diverse Wire Types: Test various wire types including single wire, flat wire, shielded wire, silicone wire, CABLE, and more. Its adaptable design ensures compatibility with your specific wire harness materials.

-

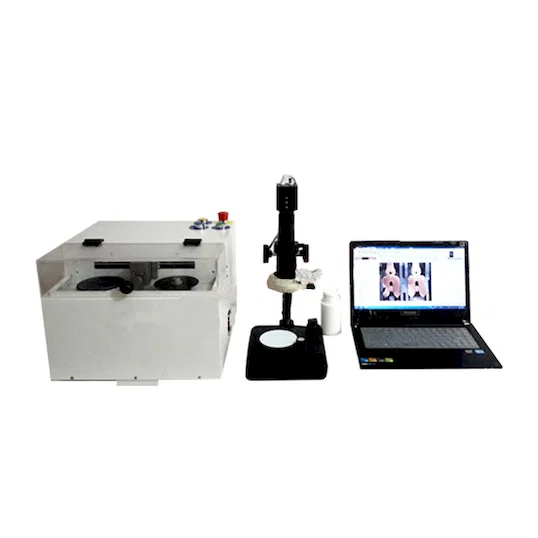

Tests Composite Products: Expand your testing capabilities beyond standard wire harnesses. This machine can also test PCB boards, USB, HDM1, TYPE-C, patch cords, and other composite products, making it a comprehensive testing solution for diverse electronic assemblies.

-

Appearance Defect Detection (Electronic Products): Extend its application to include visual inspection. The machine can assist in the appearance defect detection of electronic products, such as PCB solder joints, providing an additional layer of quality assurance.

-

Wide Industry Application: This Double Row Housing Wires Sequence Test Machine is ideally suited for a broad spectrum of industries, including:

-

Consumer Electronics: Ensuring the reliability of cables and harnesses in smartphones, laptops, and other consumer devices.

-

Automotive: Guaranteeing the performance and safety of automotive wire harnesses, critical for vehicle functionality.

-

Medical Care: Meeting the stringent quality standards required for medical device wiring, ensuring patient safety and device reliability.

-

Communications: Testing cables and harnesses used in telecommunications infrastructure and equipment.

-

Machinery and Equipment: Verifying the integrity of wiring systems in industrial machinery and equipment.

-

New Energy: Supporting the rapidly growing new energy sector by testing harnesses

used in electric vehicles, solar panels, and other renewable energy

technologies.

Product Specifications:

|

Product Name

|

2-Row Wire Harness Color and Continuity Tester

|

|

Test Range Width

|

1-50mm

|

|

Voltage

|

200-240VAC 50/60HZ

|

|

Weight

|

20kg

|

|

Tamaño del embalaje

|

560440450mm

|

|

Ambiente de trabajo

|

Temperatura 0-40°C, Humedad relativa <80%

|

|

Prueba de color

|

Secuencia de cables con desorden de color, extravío, PIN incorrecto

|

|

Prueba de continuidad

|

Continuidad de 64 pines / circuito abierto / Prueba de apertura instantánea

|

|

Indicación del resultado de la prueba

|

Transmisión de voz, bloqueo NG

|

|

Productos aplicables

|

Mazo de cables automotriz, 2 filas de un solo extremo, 2 extremos de 2 filas, Tipo-C, HDM1, USB, cable a PCB, personalizado

|

Serie de productos:

El

La máquina de prueba de secuencia de cables de carcasa de doble fila es parte de un

Serie completa de probadores de secuencia de mazos de cables, que ofrecen

Soluciones adaptadas a diversas necesidades y presupuestos:

-

Prueba de secuencia de cables de una sola función, una sola fila / 2 filas: una solución dedicada para la verificación básica de secuencias de cables.

-

2 en 1, una sola fila / 2 filas, secuencia de cables y prueba de continuidad: combina la secuencia de cables y las pruebas de continuidad para mejorar el control de calidad.

-

3 en 1, una sola fila / 2 filas, secuencia de cables y continuidad e impresión puntual: agrega impresión matricial para trazabilidad y pruebas completas.

-

Prueba de mazo de cables compuesto de carcasa de extremo múltiple: Diseñado específicamente para arneses de cables complejos de múltiples extremos y ensamblajes compuestos.

Conclusión: